I remember back 18 years ago when Dassault Systèmes acquired SRAC and the concept of Design Validation began. The idea that Designers & Engineers could use FEA software as an integral – almost daily part of the design process was in it’s infancy. This is where SOLIDWORKS has always been a leader, making difficult activities quick and easy to solve, for ALL.

This year I got to experience this first hand. Mark Schneider was busy preparing Model Mania® 2019. As we were going through the part, he asked me a simple question.

“Any thoughts on a quick and easy simulation for this year’s model?”

I quickly gave my best, non-committal answer… “It depends”. The “depends” is the story. Let’s have a look!

Depends #1 – Super Quick & Easy:

The first thought was to do something very quick and easy. This IS Model Mania after all. The point is more about modeling and design change speed than an in depth simulation. A simple LOAD on the attachment holes in the arms and a FIXED back face.

I

I

While this setup gives an answer back in seconds, it’s just not realistic at all. The FIXED back face basically represents that the entire part is glued to a large structure – not the case here with the mounting holes.

Depends #2 – Quick & Easy:

Taking a second look at the setup, a better but still fast way to setup the problem is to use a FIXED restraint on the cylindrical face of the mounting hole. Using COPY STUDY takes all the effort out of creating this new setup, just copy, change the restraint, and run again.

This time the results looked pretty reasonable. A lot of stress at the mounting hole, which is easy to understand, but the stress and deformation look like I would expect.

Even better, the solver was finished in just a few seconds! The entire process from setup through results was done in under a minute. This looks to be the perfect setup for Model Mania!

Depends #3 – Even Better & Still Fast:

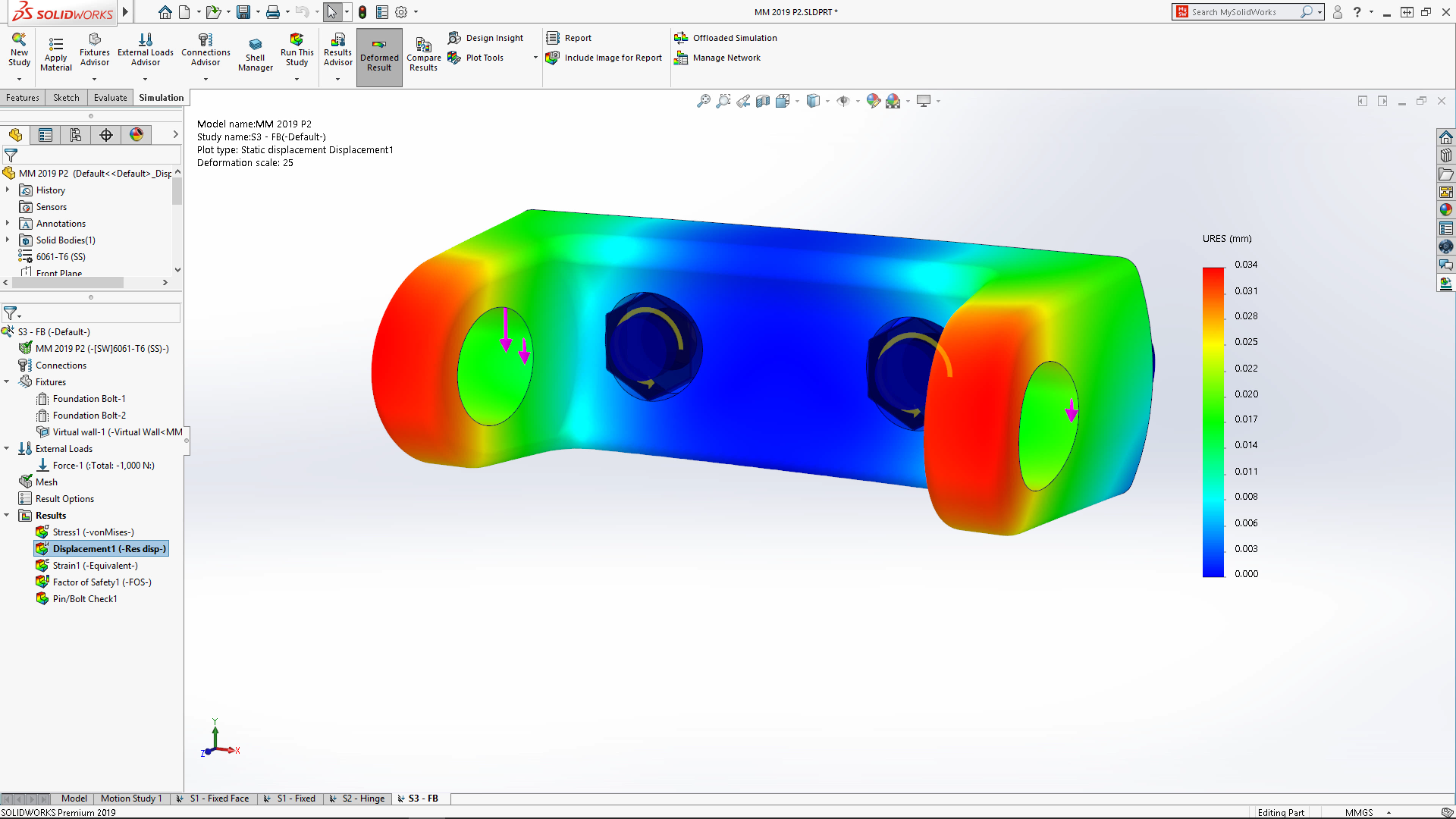

Like many, although the previous results looked good and an ideal solution for Model Mania, there was a lingering question – could I make it even better and still just as fast. Thinking more about the setup, rather than using a FIXED constraint on the cylindrical face of the mounting holes, a FIXED-HINGED restraint should be better. Additionally, the mounting face would certainly be attached to a large flat surface which would prevent it from deforming in that direction, a perfect use case for a VIRTUAL WALL. Again, using COPY STUDY, this third setup was fast, simply edit the fixture and add the VIRTUAL WALL.

The stress results from this setup were higher than the previous setup, with concentrations in the mounting holes like the previous setup. They also have a different pattern, more evenly dispersed from mounting holes to the large fillets between the base and the arms. The displacement was also different due to the VIRTUAL WALL allowing for separation but not penetration.

This study took longer to run due to the VIRTUAL WALL, however; not an excessive amount of time at 1 minute 40 seconds.

Depends #4 – Perfection

Having gone this far, we all face the “GOOD ENOUGH” versus “PERFECTION” scenario. Since SOLIDWORKS Simulation makes it so easy to try one more setup, it was time try the most realistic setup possible. This required removing the FIXED-HINGED restraint and adding FOUNDATION BOLTS to the mounting holes. FOUNDATION BOLTS use the VIRTUAL WALL from the previous setup and allow for material selection, fastener strength data, and even a pre-load.

This solve time for this setup was longer, to be expected with both the VIRTUAL WALL and FOUNDATION BOLTS, although not excessive at just under 4 minutes.

The results from this setup showed stress at the same level as the second study and displacement matching the third setup due to the VIRTUAL WALL. These results are clearly the best with the model showing the expected behavior in the simulation.

An additional bonus to this setup, SOLIDWORKS Simulation provides BOLT CHECK results. A quick check shows whether each bolt will support the load or fail and complete details of shear, axial, and bending stress are also delivered. This is valuable information and helps users make decisions early in the design process.

Design Validation for All – Wrapping up all the Depends

Without a question, in 2019, simulation and design are permanently connected as a single discipline. It is almost impossible to be competitive in any market today without using simulation tools in the design process. Simulation users are always balancing speed and accuracy, demanding simultaneous improvements to both. This is where SOLIDWORKS Simulation really shines brightest!

Comparing the four scenario’s is a great example. The first setup is simply not realistic. No work was lost using COPY STUDY and selecting new fixed faces for the second attempt and most importantly, all of this was done in minutes if not seconds! While not perfect, these results are more than adequate for early design validation as we did for Model Mania 2019. The final step is what really shows the power of SOLIDWORKS Simulation as a tool for ALL. Leveraging the initial “Design Validation” study and making simple changes to the setup delivered high fidelity results on the design model plus bonus results on the bolt connectors, all in just a few minutes.

SOLIDWORKS make simulation “Quick and Easy” while delivering accurate results fast.

Try SOLIDWORKS Simulation on your next project and share your feedback with us.

Originally posted in the SOLIDWORKS Tech Blog.