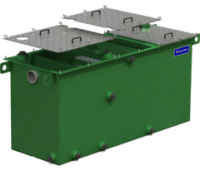

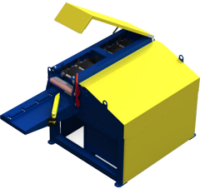

Industries Desjardins have been in business for 145 years and are well established in their region. They were originally dedicated to producing farming equipment however they have since expanded and now also manufacture fuel tanks, oil separators and sawmill machinery.

Industries Desjardins have been in business for 145 years and are well established in their region. They were originally dedicated to producing farming equipment however they have since expanded and now also manufacture fuel tanks, oil separators and sawmill machinery.

Every piece of equipment manufactured by Industries Desjardins can be customised to meet specific requirements. They’re also fully configurable using a range of equipment and accessories.

Every piece of equipment manufactured by Industries Desjardins can be customised to meet specific requirements. They’re also fully configurable using a range of equipment and accessories.

How Did You Configure-To-Order (CTO) Before DriveWorks?

“Before we started using DriveWorks every sale needed countless hours of input from specialised technicians to import and modify CAD models and prepare the production drawings. It was time consuming so we needed to find a way to streamline the process.” – Serge Fournier—Design Project Manager.

The Benefits of Using DriveWorks

“DriveWorks provided the tools to keep our staff focused on high value tasks while the software handles the easy stuff. DriveWorks has helped to cut approximately 85% off the drawing time on an average project.

“DriveWorks provided the tools to keep our staff focused on high value tasks while the software handles the easy stuff. DriveWorks has helped to cut approximately 85% off the drawing time on an average project.

Our library of CAD models has decreased significantly and thus contributed to lower engineering maintenance time on our CAD database.

Merging our high volume products to DriveWorks helps us to keep our project lead time as low as possible while our staff are used more efficiently in other areas.”

Implementing DriveWorks

“DriveWorks software was easy to learn and the interface is very user friendly. We worked with DriveWorks and our Value Added Reseller, SolidXperts, who both provided great support for us throughout the implementation process.”

“DriveWorks software was easy to learn and the interface is very user friendly. We worked with DriveWorks and our Value Added Reseller, SolidXperts, who both provided great support for us throughout the implementation process.”

Time Saving Metrics

Previous system: countless hours

Previous system: countless hours

With DriveWorks: 85% reduction on drawing time