Winder Power standardize design process and reduce lead time using DriveWorks

Winder Power specialises in the design, build, deployment and management of power transformers and distribution transformers. They serve a wide range of customers in the utilities, renewable energy, and industrial sectors across the UK and internationally.

Why DriveWorks?

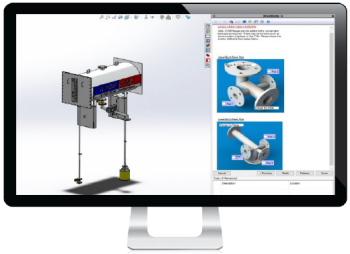

Before using DriveWorks, Winder Power designed to order using SOLIDWORKS, design tables and equation based parts.

Winder Power began with DriveWorks Solo and then upgraded to DriveWorks Pro. They have found that the move to DriveWorks Pro has allowed them to merge their existing DriveWorks Solo projects together, which has streamlined the interface for their users.

“We have also taken advantage of the additional functionality available within DriveWorks Pro in order to directly extract information from excel spreadsheets that exist elsewhere in our organization.” Luke Beeson – Mechanical Design Engineer.

Who Uses DriveWorks at Winder Power?

Winder Power are currently using DriveWorks in their engineering department for generating models and drawings for several components within their design process.

These include:

– Full transformer assemblies

– Transformer active part clamp systems

– Oil conservators

– Cooler bank A-Frames

– Transformer rating plates

These components are all based on standardised design rules and are either generated complete with the drawings and assemblies, or partially generated. The partially generated projects are then developed to completion by their engineers.

The Benefits

DriveWorks Pro has allowed Winder Power to design components in much shorter time frames, with reduced errors due to the more rigid design process. Therefore they can offer their customers a reduced product lead time.

Overall the main benefits of using DriveWorks for Winder Power are the time savings and also the ability to build fixed design methodology into their projects.

“Merging projects further and adding additional functionality is a continuous process for us now, and I estimate we add additional functionality at least every couple of months. We are also currently looking into what benefits DriveWorks Pro can offer different departments outside of engineering.”