More Power for the SOLIDWORKS Design to Manufacture Solution

SOLIDWORKS 2019 delivers more power for the SOLIDWORKS Design to Manufacture Solution suite of tools including improvements to SOLIDWORKS MBD, SOLIDWORKS CAM and SOLIDWORKS Inspection.

Go from Concept to Manufactured Products Even Faster

SOLIDWORKS 2019 delivers a powerful suite of tools that maximize the productivity of your design and manufacturing resources, helping you create great products faster, and more cost effectively.

Putting the model at the centre of the process, using SOLIDWORKS Model Based Definition, all the Product Manufacturing Information or “PMI” required to manufacture your design can be applied directly to the 3D geometry, removing the cost and time consuming overhead of creating 2D drawings.

When sharing parts for use in downstream manufacturing processes, derived parts provide an associative and controlled method of referencing the original design. Enhancing the workflow further, in SOLIDWORKS 2019 you can now copy the pre-existing Dimension and Tolerance Schemes to a derived part, eliminating the need to recreate any PMI.

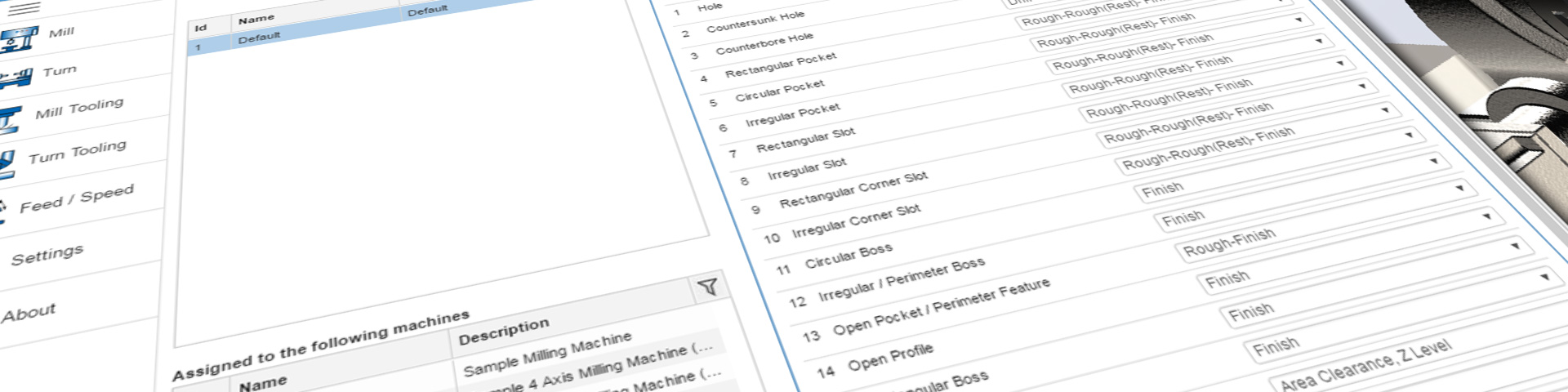

When you’re ready to manufacture your design, SOLIDWORKS CAM delivers fully integrated knowledge based CNC programming. New for SOLIDWORKS 2019, you can now leverage PMI for programming turned parts. SOLIDWORKS CAM automatically applies your preferred machining strategies to the part, based on the tolerance scheme. If the tolerance specification of a feature changes, SOLIDWORKS CAM automatically updates the machining operations using predefined rules that match your manufacturing best practices.

SOLIDWORKS CAM 2019 reduces programming time even further, by introducing a wealth of new productivity enhancements.

- Utilize the power of configurations to define multiple manufacturing set ups and operations on a single part.

- New custom tool and corner slow down options increase tool life and improve surface finish.

- “Move” machining features from their original location to any position, making it quick and easy to machine to mid tolerance without changing model geometry.

Parts that once took hours or even days to program can now be programmed in minutes!

At the same time, using SOLIDWORKS Inspection your quality team can generate first article inspection reports that are ready to be utilized by quality control as final inspection documentation. New projects can be defined with just a few simple clicks. SOLIDWORKS Inspection instantly recognizes and extracts part numbers, names, revisions, notes and other critical information from your drawing. SOLIDWORKS 2019 adds support for Hole Tables, and provides greater flexibility over the grouping of characteristics, ensuring first article inspection reports meet industry standards and requirements specific to your organization.