Enhance Your Programming Automation and Use of MBD Data

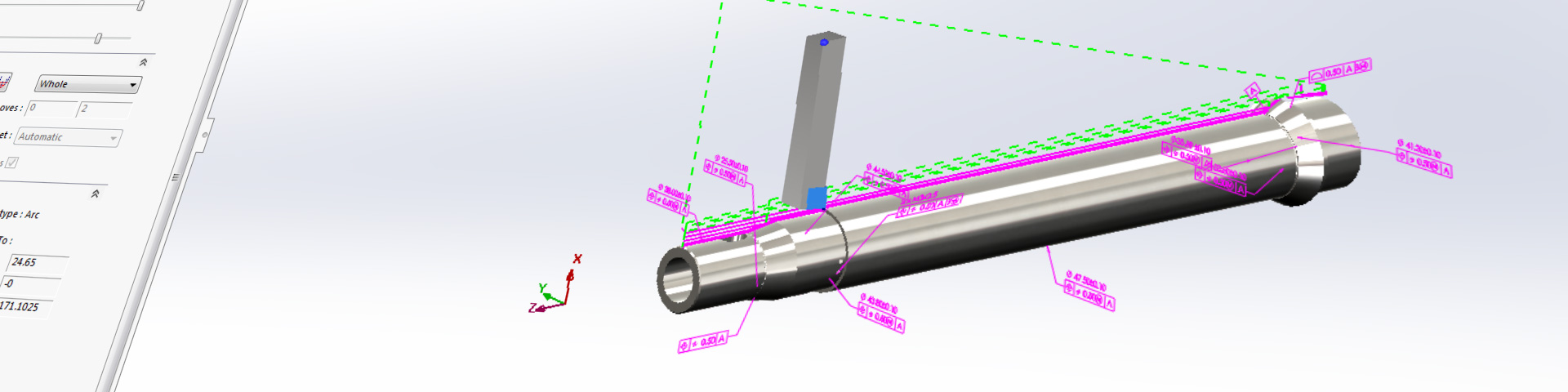

Apply tolerance specific machining strategies for turned components.

Enhance Your Programming Automation and Use of MBD Data

Tolerance-Based Machining in SOLIDWORKS CAM 2019 introduces some powerful new capabilities that dramatically reduce the time required to generate CNC programs for turned parts with close tolerances and surface finish requirements.

Leveraging DimXpert dimensions and Model-Based Definition (MBD) information applied directly to the model, SOLIDWORKS CAM automatically applies your preferred machining strategies to the part based on the tolerance scheme, with just a single button click.

Any dimension and tolerance scheme modification, however small, can often dictate a change in the operations required to machine the part to the correct size, leading to delays on the shop floor. Tolerance-based machining’s powerful rules-based approach lets you set default machining strategies for undersize, nominal, and oversize for any given tolerance size range. Re-running tolerance-based machining with new tolerance values results in a new set of operations complete with preferred tools, feeds, speeds, and cut depths automatically selected to meet the strategies requirements.

Finally, all that’s left to do is calculate the toolpaths, and they are ready to be outputted as NC programs.

Tolerance-Based Machining in SOLIDWORKS CAM 2019 streamlines design to manufacture, leveraging the power of MBD to automate CNC programming and reduce overall delivery times.